Hammer Spring Alternation in CZ 75

CASE STUDY: Hammer Spring Alternation in CZ 75

This simple example demonstrates how the TriggerScan™ system can assist in

replacing a hammer spring. The instrument is used to examine the

characteristics of the springs and also to determine the trigger profile and

lock time before and after the spring alternation.

Problem Background: A popular local gunsmith was lightening the trigger pulls on his customers Berettas, CZ 75’s and other handguns by installing aftermarket hammer springs which were slightly softer but longer than the factory originals. He claimed, that the longer and softer spring gives a lighter trigger while still providing enough energy for the firing mechanism, although he did not have any instrumentation to back it up. I obtained one of his aftermarket springs for my CZ 75 and used the TriggerScan™ instrument to document my work.

The Spring Test:

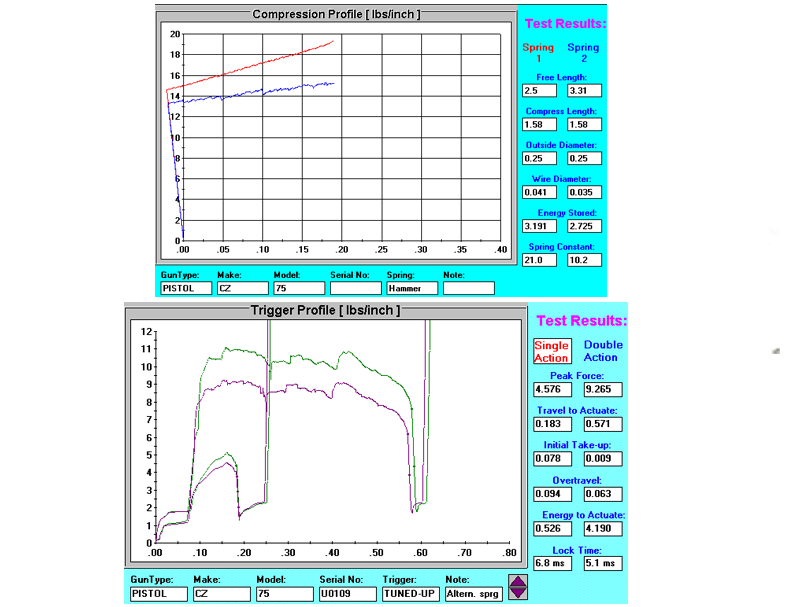

The hammer spring in this pistol operates within 1.58" (hammer fully

cocked) and 1.76" (hammer fully dropped), which provides 0.18" for

the spring compression. The following chart obtained with TriggerScan™ compares

the original spring (Spring 1) with the aftermarket spring (Spring 2). The

instrument examines the springs by compressing each of them from 1.76" to

1.58" in length. Then, for each spring it automatically determines the

"Energy Stored" (which equals the area under the curve) and the

"Spring Constant" (also called the stiffness). Note that under normal

operation the traces start on the left side of the vertical axis, since the

datapoints are compensated for deflection of the instrument’s sensor finger

under load.

Original spring: Red profile. The spring has a free length of

2.5" and O.D of 0.25". It is made of 33 coils of 0.041" steel

wire. The spring exhibits fairly smooth linear characteristics. It stores 3.1

inch*lb of energy and has a stiffness of 21 lb/inch.

New spring: Blue profile. The spring has a free length of 3.3"

and O.D of 0.25". It is made of 33 coils of 0.035" steel wire. The

spring exhibits linear characteristics. The jerky spots are caused by the

spring coils dragging on the guiding rod. The spring stores 2.7 inch*lb of

energy, which is 12% less than the original, and has a stiffness of 10 Lb/inch.

Trigger profile with the original spring: shown in green. In single

action the trigger breaks at 5.2 pounds and has .182 inch of travel to fire. In

double action it breaks at 11.1 pounds and has .579 of travel. In both cases,

there is a moderate amount of initial take-up and overtravel. Overtravel is

greater in single action mode. The energy or amount work needed to actuate the

trigger, graphically represented by the area under the curve is 0.557

inch*pounds in single action and 5.045 inch*pounds in double action. This means

that 10 times higher effort is needed to fire the gun in double action than in

single action mode. Lock time is 5.7 milliseconds in single action and 4.4

millisecond in double action.

Trigger profile with the new spring: shown in purple. The trigger

breaks at 4.6 pounds in single and 9.3 pounds at double action mode. The travel

remains about the same. The energy needed in order to actuate the trigger is

0.526 inch*pounds in single action and 4.190 inch*pounds in double action. This

means that almost 8 times as much effort is needed to fire the gun in double

action than in single action mode. Lock time is 6.8 ms in single action and 5.1

ms in double action.

Test fire: the pistol was tested with the new spring over a period of

several weeks. I liked the lighter trigger pull, which allowed more precise

shooting, especially in double action pull. After a while, I had a misfire.

Misfires occurred repeatedly every 50 to 100 rounds, with various kinds of

ammo.

Conclusion: The aftermarket hammer spring lightened the trigger by

12% (SA) and 16% (DA). It took 6% less effort (SA) and 17 % less effort (DA) to

fire the gun with the new spring. This allowed more precise shooting, but on

the other hand it lowered the safety margin against an unintended shot. The

lock time increased with the new spring by 19% (SA) and 16% (DA). The energy of

the firing mechanism, determined from the spring profile, was about 15% lower

with the new spring, which resulted into 1 to 2 misfires in every hundred

rounds fired.

After this test I decided it was a good idea to reinstall the factory

original hammer spring in this gun.

Albert Dvorak